High-density polyethylene (HDPE) geomembranes for landfills

Short Description:

HDPE geomembrane liner is blow molded from polyethylene polymer material. Its main function is to prevent liquid leakage and gas evaporation. According to the production raw materials, it can be divided into HDPE geomembrane liner and EVA geomembrane liner.

Products Description

HDPE geomembrane is one of the geosynthetic materials, it has excellent environmental stress cracking resistance, low temperature resistance, anti-aging, corrosion resistance, as well as a large temperature range and long service life, widely used in domestic waste landfill impermeability, solid waste landfill impermeability, sewage treatment plant impermeability, artificial lake impermeability, tailings treatment and other impermeability projects.

Performance Characteristics

1. Does not contain chemical additives, does not undergo heat treatment, is an environmentally friendly building material.

2. Has good mechanical properties, good water permeability, and can resist corrosion, anti-aging.

3. With strong buried resistance, corrosion resistance, fluffy structure, with good drainage performance.

4. Has a good coefficient of friction and tensile strength, with geotechnical reinforcement performance.

5. With isolation, filtration, drainage, protection, stability, strengthening and other functions.

6. Can adapt to the uneven base, can resist the damage of external construction, creep becomes smaller.

7. The overall continuity is good, light weight, convenient construction.

8. It is a permeable material, so it has good filtration isolation function, strong puncture resistance, so it has good protection performance.

Product Specifications

GB/T17643-2011 CJ/T234-2006

| No. | Item | Value | |||||

| 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | ||

| 1 | min density(g/㎝3) |

0.940 | |||||

| 2 | yield strength(TD, MD), N/㎜≥ | 15 | 18 | 22 | 29 | 37 | 44 |

| 3 | breaking strength(TD, MD), N/㎜≥ | 10 | 13 | 16 | 21 | 26 | 32 |

| 4 | yield elongation (TD, MD), %≥ | 12 | |||||

| 5 | breaking elongation (TD, MD), %≥ | 100 | |||||

| 6 | (average rectangle tear strength(TD, MD), ≥N | 125 | 156 | 187 | 249 | 311 | 374 |

| 7 | puncture resistance, N≥ | 267 | 333 | 400 | 534 | 667 | 800 |

| 8 | stress crack resistance, h≥ | 300 | |||||

| 9 | carbon black content, % | 2.0~3.0 | |||||

| 10 | carbon black dispersion | nine of 10 is grad I or II, less than 1 if grad III | |||||

| 11 |

oxidative induction time(OIT), min | standard OIT≥100 | |||||

| high pressure OIT≥400 | |||||||

| 12 | oven aging at80℃(standard OIT retained after 90 days), %≥ | 55 | |||||

Geomembrane Usage

1. Landfill, sewage or control the waste residue seashores seepage.

2. Lake dam, tailings dams, sewage dam and reservoir, channel, storage of liquid pools(pit, ore).

3. The subway, tunnel, anti-seepage lining of basement and tunnel.

4. Seawater, freshwater fish farms.

5. Highway, the foundations of the highway and railway; the expansive soil and collapsible loess of the waterproof layer.

6. Anti-seepage of roofing.

7. To control the roadbed and other foundation saline seepage.

8. Dike, the front of the sam foundation seepage prevention bedding, level of vertical impervious layer, construction cofferdam, waste field.

Picture Display

Usage scenarios

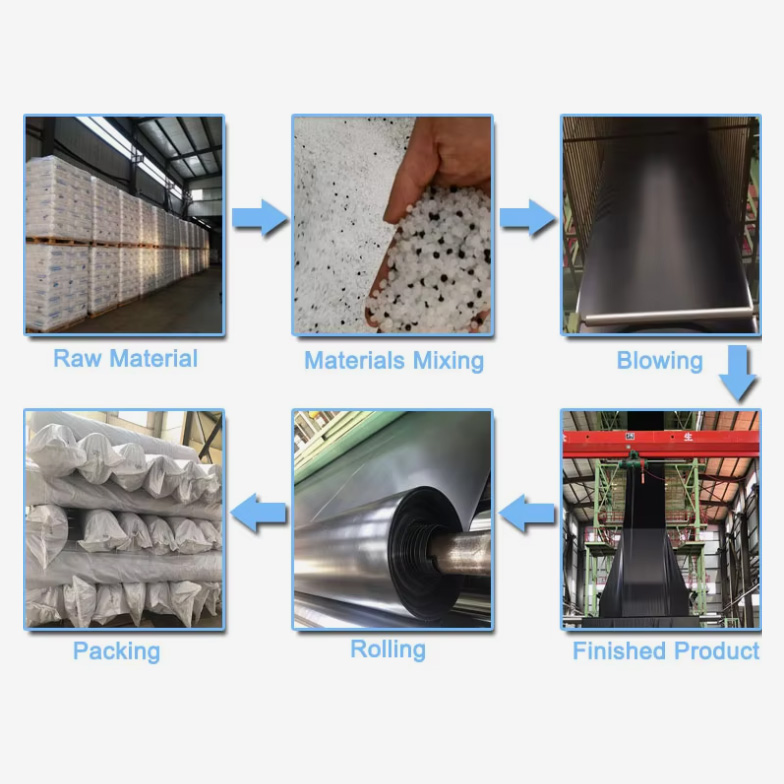

Production process